-

Austria | English

-

Belgique | Français

-

Belgium | English

-

Bulgaria | English

-

Croatia | English

-

Czechia | English

-

Denmark | English

-

Estonia | English

-

Finland | English

-

France | Français

-

France | English

-

Germany | English

-

Greece | English

-

Hungary | English

-

Ireland | English

-

Italy | English

-

Latvia | English

-

Lithuania | English

-

Luxembourg | English

-

Netherlands | English

-

Poland | English

-

Portugal | English

-

Romania | English

-

Slovakia | English

-

Slovenia | English

-

Spain | English

-

Sweden | English

-

Suisse | Français

-

Switzerland | English

-

United Kingdom | English

LE SAVOIR-FAIRE

Artists in silversmithing

ERCUIS, LE SAVOIR-FAIRE

The manufacture of cutlery and holloware bearing the Ercuis hallmark requires numerous manual steps carried out by expert silversmiths throughout specific production phases. This unique and valuable savoir-faire passed down through the generations since the 19th century makes Ercuis one of France’s greatest silversmiths.

UP TO 45 STEPS TO MANUFACTURE A CUTLERY

It all starts with the press cutting of sheets of metal, before the laminating stage which stretches the metal. These metal blanks are then pressed with steel moulds in presses, revealing the final shapes and designs of the cutlery.

The moulds are nowadays manufactured using high-tech machine tools, before being perfected manually by the engraver, who refines the details of designs with specific engraving tools. To produce a single piece of cutlery, four moulds are necessary, corresponding to the two successive stages of the cutlery press.

After shaping on the presses, the finishing of the cutlery requires a lot of meticulous and extremely precise manual skills.

Deburring

It removes excess metal and major roughness to give the part its final contour.

Smoothing

It makes the sides of each piece smooth.

Cutting the fork tines

The tines of forks are thinned one by one, above, below and on the sides to make them sharp.

Knives assembly

The handle and the blade of a knife are manufactured separately during the first steps. Their assembly requires precision and patience.

Polishing and brightening

Using increasingly fine abrasives, these operations result in a perfectly smooth and shiny piece. These operations are carried out manually using buffers and volcanic powder.

Manual know-how

The manual know-how of the polishers is decisive in preserving the decorations and perfecting the details of the pieces.

Deburring

It removes excess metal and major roughness to give the part its final contour.

Smoothing

It makes the sides of each piece smooth.

Cutting the fork tines

The tines of forks are thinned one by one, above, below and on the sides to make them sharp.

Knives assembly

The handle and the blade of a knife are manufactured separately during the first steps. Their assembly requires precision and patience.

Polishing and brightening

Using increasingly fine abrasives, these operations result in a perfectly smooth and shiny piece. These operations are carried out manually using buffers and volcanic powder.

Manual know-how

The manual know-how of the polishers is decisive in preserving the decorations and perfecting the details of the pieces.

The finest craftsmanship

The Ercuis workshops produce unique and unforgettable sterling silver, gilt or silver plated creations, forged by the exceptional talent of our master silversmiths. casters, chisellers, casters and engravers.

Silverplating

THE BEAUTY OF SILVER

Several successive operations are performed before the silver plating: polishing and degreasing so that the silver can perfectly adhere to the base metal. Deburring removes significant roughness, then sanding and polishing make a piece perfectly smooth and shiny. The perfectly rinsed piece can then be dipped into a silver plating electrolysis bath.

Ercuis insists on the very high quality of silver plate for its flatware. The coating of respects the standard of 33 microns required for the square grade 1 hallmark (superior quality).

Day by day, use and subsequent washing in a dishwasher will give them a nice patina because silver, like leather, is one of the few materials that becomes more beautiful with age.

Final touches

After silver plating, finishing touches are completed: the patina of certain decorations, the brightening that gives the final brilliance to pieces using soft buffers, stamping the hallmark, final inspection for quality control, and, lastly, the boxing in individual packaging specifically designed for protection of the pieces.

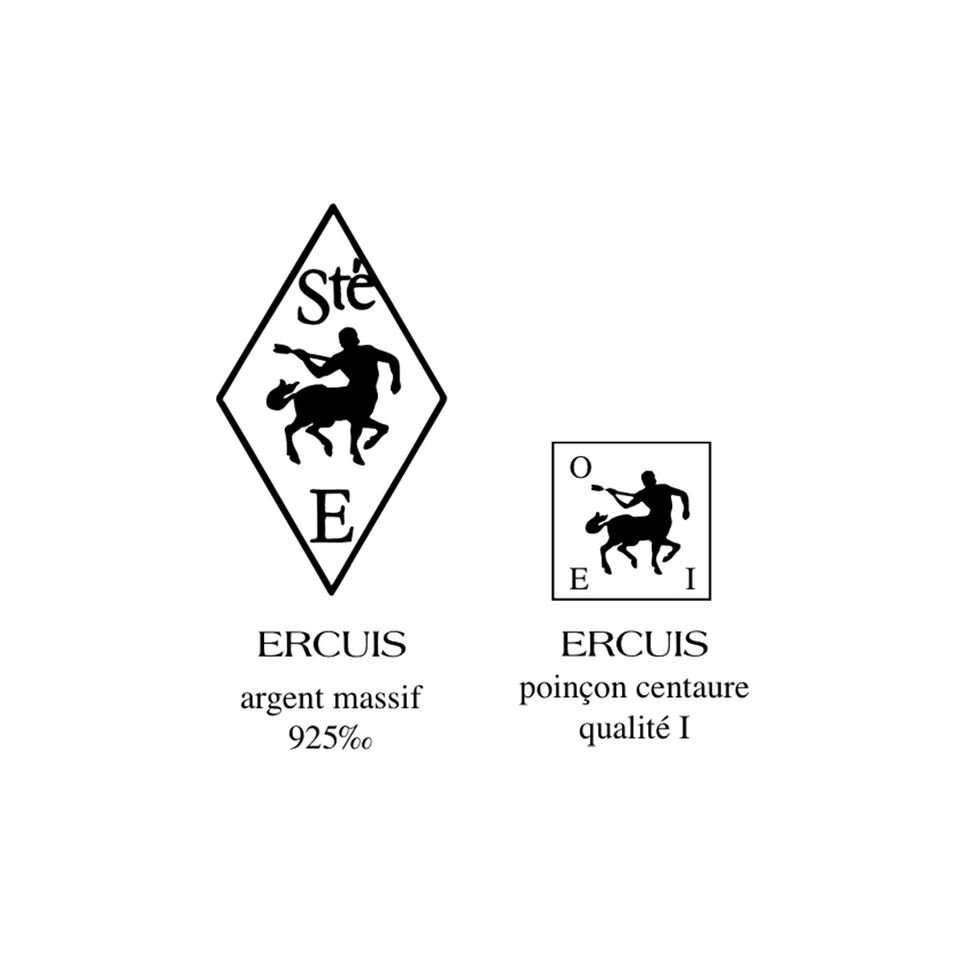

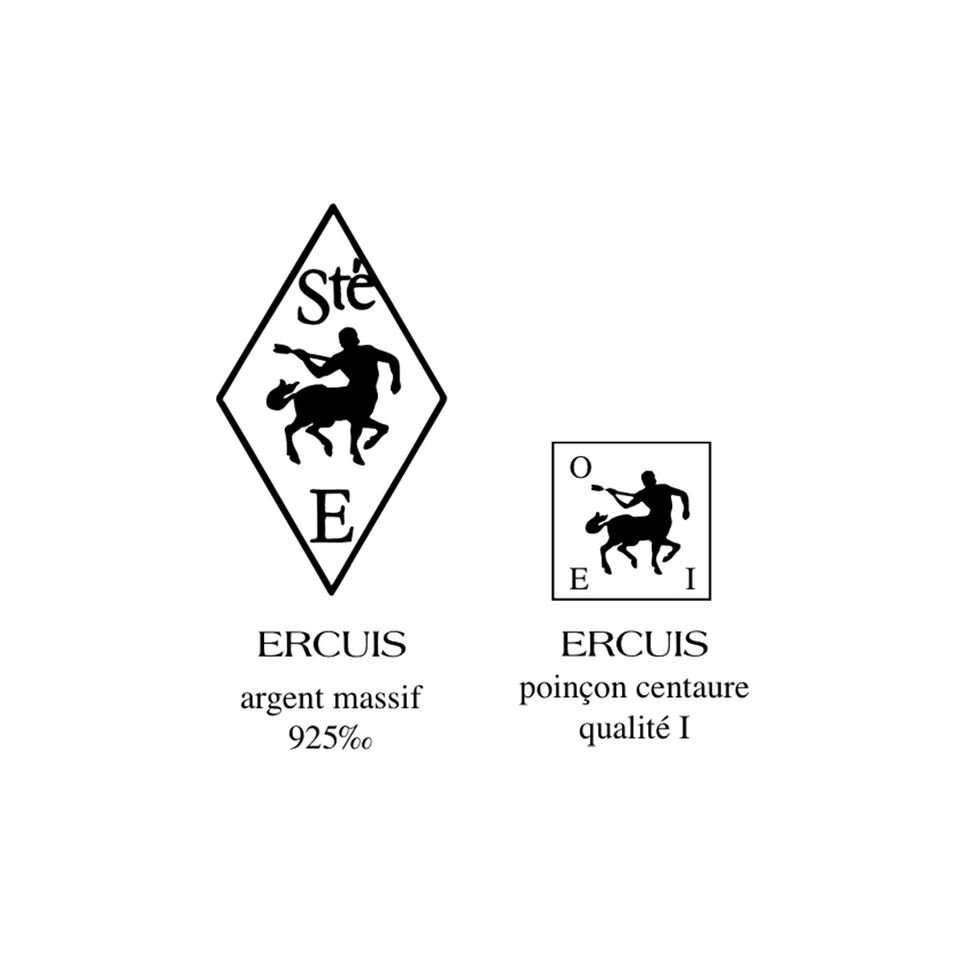

Hallmarks

For sterling silver, two hallmarks are required in France: a master hallmark with the initials and the symbol of the manufacturer in a diamond shape and the official State hallmark displaying the head of Minerva and a number corresponding to grade I or II. The silver grade corresponds to its purity level as it is always combined with copper to be sufficiently strong. 1st grade: the alloy is composed of 925 thousandths of pure silver and 75 thousandths of copper.

Final touches

After silver plating, finishing touches are completed: the patina of certain decorations, the brightening that gives the final brilliance to pieces using soft buffers, stamping the hallmark, final inspection for quality control, and, lastly, the boxing in individual packaging specifically designed for protection of the pieces.

Hallmarks

For sterling silver, two hallmarks are required in France: a master hallmark with the initials and the symbol of the manufacturer in a diamond shape and the official State hallmark displaying the head of Minerva and a number corresponding to grade I or II. The silver grade corresponds to its purity level as it is always combined with copper to be sufficiently strong. 1st grade: the alloy is composed of 925 thousandths of pure silver and 75 thousandths of copper.

/Escale%20Enchant%C3%A9e%201%20-%201536%20x%201536.jpg?sw=960&sh=960)

/R%C3%A9gence%201%20-%201536%20x%201536.jpg?sw=502&sh=502)

/Louis%20XV%20Jardini%C3%A8re%202-%201536%20x%201536.jpg?sw=502&sh=502)

/Louis%20XV%207%20-%201536%20x%201536.jpg?sw=502&sh=502)

/Escale%20Enchant%C3%A9e%201%20-%201536%20x%201536.jpg?sw=80&sh=80)